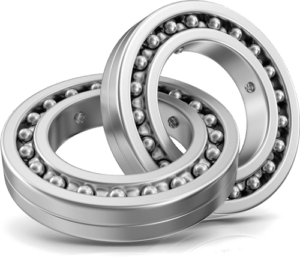

Radial ball bearings are widely used in numerous industries due to their versatility and numerous advantages. These bearings are designed to support radial loads, providing smooth and efficient rotational motion.

One of the key advantages of radial ball bearings is their ability to withstand both radial and axial loads. This makes them suitable for applications where there is a combination of forces acting on the bearing. Their design enables them to distribute the load evenly, minimizing friction and reducing wear and tear.

Another advantage is their high rotational speed capability. Radial ball bearings are engineered to operate at high speeds without compromising performance or durability. This makes them an ideal choice for applications that require rapid and precise rotational motion, such as electric motors, automotive components, and industrial machinery.

Additionally, radial ball bearings are known for their reliability and longevity. They are constructed with high-quality materials and precision manufacturing, ensuring consistent performance over an extended period. Their low friction characteristics contribute to energy efficiency and reduced heat generation.

Overall, radial ball bearings offer exceptional load capacity, high-speed capability, and long service life. Their widespread application in industries such as manufacturing, automotive, and aerospace is a testament to their reliability and performance, making them a vital component in various mechanical systems.

Leading stockist of Industrial Bearings & Fasteners

Leading stockist of Industrial Bearings & Fasteners