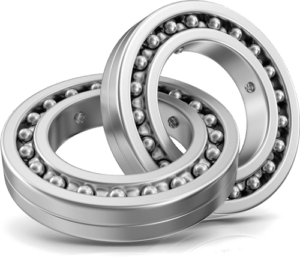

Needle bearings are widely used in various mechanical systems due to their high load-carrying capacity and compact design. However, to ensure optimal performance and durability, these bearings often require an additional component known as a needle bearing inner ring.

A needle-bearing inner ring is a precision-machined ring that provides a hardened and ground raceway for the needle rollers. It is typically made from high-quality bearing steel to withstand heavy loads and ensure smooth rolling motion. The inner ring acts as a support for the needle rollers, reducing friction and wear within the bearing assembly.

The application of needle bearing inner rings extends across numerous industries, including automotive, industrial machinery, and aerospace. These inner rings are particularly beneficial in high-speed and high-load applications where precise motion control is essential.

One notable advantage of using needle bearing inner rings is their ability to enhance efficiency and reliability. By reducing friction and distributing loads evenly, they minimize energy losses and extend the service life of the bearing. This, in turn, leads to improved overall system performance and reduced maintenance costs.

Leading stockist of Industrial Bearings & Fasteners

Leading stockist of Industrial Bearings & Fasteners