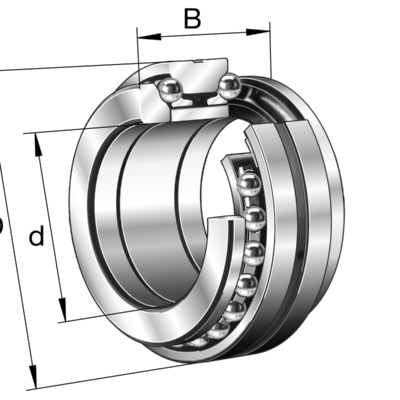

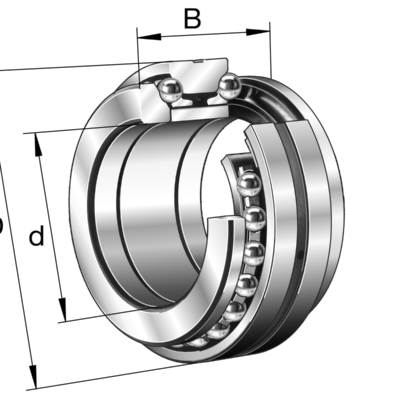

Axial angular contact ball bearings are a type of precision bearing designed to support axial loads in both directions while also being able to handle some radial loads. These bearings are commonly used in high-speed applications where accuracy and reliability are critical.

The axial angular contact ball bearing design features a row of balls arranged at an angle to the bearing’s axis, which allows it to support both axial and radial loads. The contact angle of the bearing can vary depending on the intended application, but it is typically between 15 and 40 degrees. The larger the contact angle, the higher the axial load capacity of the bearing.

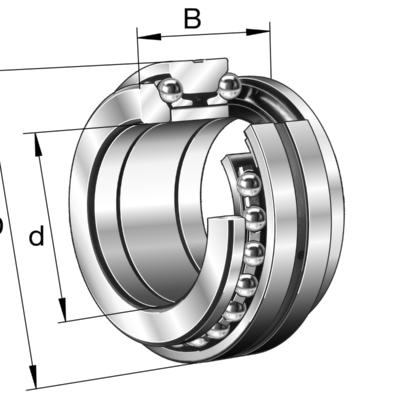

One of the main advantages of axial angular contact ball bearings is their ability to handle high speeds. The design of the bearing minimizes the contact area between the balls and the raceway, which reduces friction and heat generation. This, in turn, reduces the risk of damage to the bearing due to overheating.

Another advantage of axial angular contact ball bearings is their high accuracy. The bearings are designed with tight tolerances to ensure that the balls are properly spaced and aligned with the raceway. This results in a bearing that is capable of handling high loads with minimal deformation or wear, which is essential for maintaining accuracy and reliability over time.

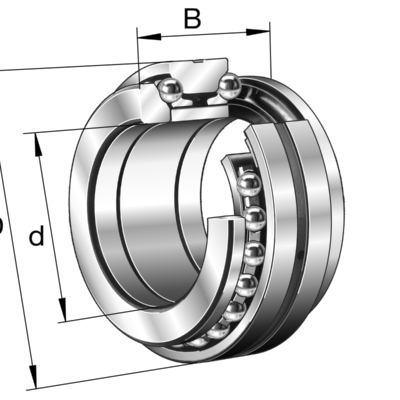

Axial angular contact ball bearings are commonly used in a variety of applications, including machine tools, robotics, and automotive components. In machine tools, they are often used in spindle assemblies to support the high axial and radial loads generated during machining operations. In robotics, they are used to support the joints and other moving parts of the robot, where high precision and accuracy are essential. In automotive applications, they are used in the transmission and suspension systems to support high loads and minimize wear and tear.

Axial angular contact ball bearings are a crucial component in many high-speed and precision applications. Their ability to handle both axial and radial loads, combined with their high accuracy and reliability, make them an ideal choice for a wide range of industries and applications.

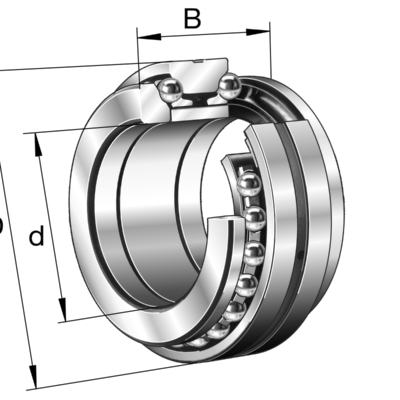

Leading stockist of Industrial Bearings & Fasteners

Leading stockist of Industrial Bearings & Fasteners