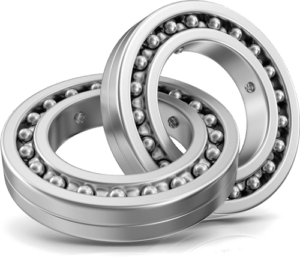

Angular contact ball bearings are a type of precision bearing designed to support high radial and axial loads in one direction. These bearings have an inner and outer raceway with a row of balls positioned at an angle to the axis of the bearing, which enables them to handle both radial and axial loads.

There are three main types of angular contact ball bearings: single row, double row, and four-point contact bearings. Single row bearings are designed with a single row of balls positioned at an angle to the bearing’s axis, making them ideal for applications that require high precision and speed. Double row bearings have two rows of balls separated by a spacer and are capable of handling higher loads than single row bearings. Four-point contact bearings have four points of contact between the balls and the raceway, which allows them to handle both axial and radial loads with high precision and accuracy.

Angular contact ball bearings are commonly used in a variety of industries and applications, including machine tools, robotics, automotive components, and medical equipment. They are ideal for applications that require high precision, accuracy, and reliability, and their ability to handle both axial and radial loads makes them a versatile and essential component in many industrial settings.

In conclusion, angular contact ball bearings are a critical component in many industries, and their three main types – single row, double row, and four-point contact – provide a range of options for various applications. Their ability to handle high loads, speed, and precision make them an ideal choice for many industries and applications.

Leading stockist of Industrial Bearings & Fasteners

Leading stockist of Industrial Bearings & Fasteners